October 28, 2021

How are delays in the supply chain impacting utility scale solar spare parts?

The global supply chain is expected to stabilize in 2022, but any small shift could cause more disruption.

Supply chain delays are happening worldwide due to COVID-19, which have a direct impact on utility scale spare parts material. More than half of global utility solar projects planned in 2022 are threatened by these issues.

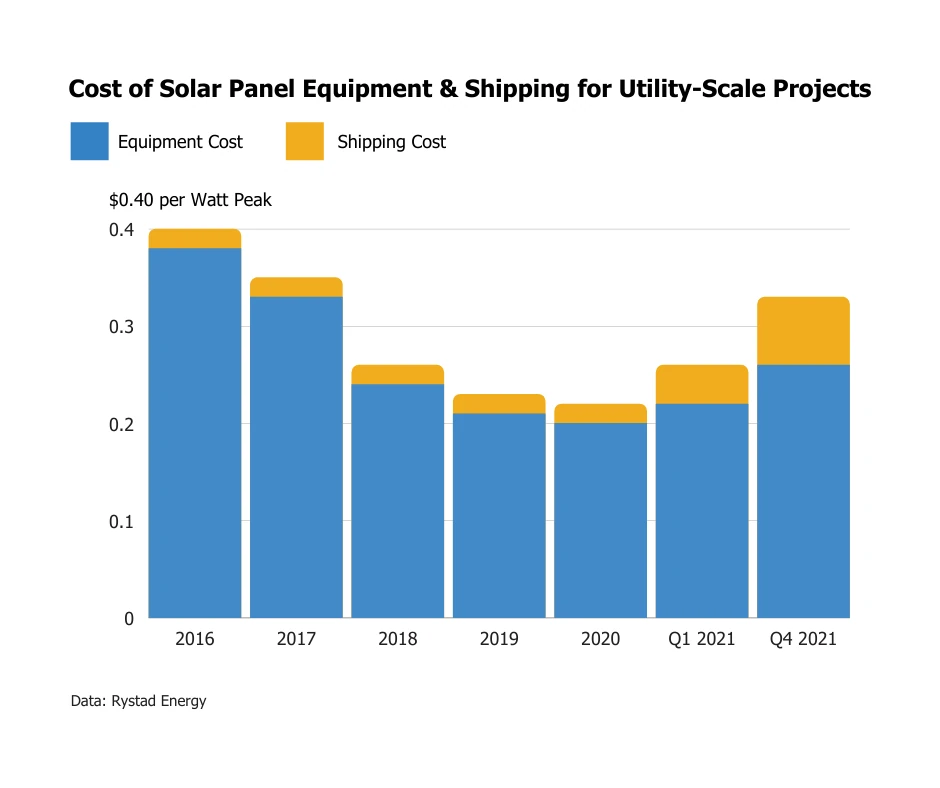

Shipping prices only continue to rise. With limited availability to source trucking and transportation and backed-up ports, we’re seeing increased complications when crossing borders. Raw material shortages—ranging from bolts to complex electrical equipment—are causing longer lead times. When you include labor shortages, it’s easy to see why what once only took 6-8 weeks is now taking 13-20 weeks to ship.

What does this mean for solar projects?

These shortages and complications can create long lead times, directly affecting utility and commercial space installs. If the lead times aren’t within the project scope, then Liquidated Damages (or LD’s) can occur. When equipment is down, that means our customers are losing money. More days with equipment down means bigger losses.

Will this resolve in the future?

Unfortunately, there isn’t a light at the end of the tunnel quite yet. The global supply chain is as fragile as it has ever been. There are projections that it will stabilize in 2022, but uncertainty truly is the only constant right now.

How to plan ahead

In order to minimize disruption and losses, we recommend getting your spare parts inventory figured out as soon as you can and ensure you’re purchasing high quality material from a reputable source. Thinking ahead and preparing by stocking up will cut down on any potential losses in the future.

One part that we are expecting to have large failures in 2022 include IGBT Stacks in SMA central inverters. These IGBT Stacks have a 6-10 year life span and many SMA inverters were first installed in 2011. Therefore, we’re expecting many O&M providers and asset owners will experience downtime this year with failed IGBT if they don’t plan ahead.

How Solar Support can help

Our efficiency is one of our greatest factors when it comes to providing for our customers.

To prepare for increased IGBT Stack failures, we have purchased a limited inventory of Semikron SEMIKUBE® IGBT Stacks. We want our customers to have an immediate solution. This allows O&M providers and asset owners to stock up before failure occurs and not be affected by large shipping delays.

For example, we had a customer who needed a SEMIKUBE® IGBT Stack on a Friday afternoon. Because we had inventory, we were able to deliver the Stacks on Saturday; their site was back up and running within 24 hours of the initial request.

What we offer

We are encouraging our customers to purchase while our IGBT Stack inventory is in stock.

- There is no increase in material costs through the end of 2021.

- We planned ahead and anticipated our customers’ needs.

- We have limited stock; first come, first served.

- We’re flexible and willing to work with you for what works most efficiently for your needs.

Planning ahead can help ensure you don’t experience any downtime.

Shipping delays aren’t going anywhere, yet, and they are causing risk and uncertainty for many O&M providers and asset owners. So we encourage you to be prepared, plan ahead and ensure your spare parts inventory is fully stocked.

Are you ready to stock up on SEMIKUBE® IGBT Stacks? You can learn more by requesting a quote or scheduling a demo call.